Charter Steel’s EV team was formed to answer an industry question, “what happens when you eliminate the engine and the drive train of an entire vehicle and replace it with an electric motor?”

Our collection of

technical service engineers (TSEs), automotive specialists, strategy experts, and marketing masterminds have collaborated on the processes and resources needed to deliver quality steel for years to come. Our EV team has committed their efforts to understanding this specific market need so they can best serve current and future customers.

The EV Industry

In the past 10 years EVs have grown from .3% of the total auto production to nearly 10% expected in 2023. That growth rate is expected to continue accelerating throughout the next decade, thanks to consumer demand coupled with government support.

Specifically, there are implications of how the EV market will impact the steel industry based on the materials required to produce EVs and their components. Will EVs displace steel demand? What are the differences in the makeup of fastening products? How do other components need to change to support increased vehicle weight? These are looming questions for those in the EV space to work through.

The Difference Between Internal Combustion Engines and Electric Vehicles

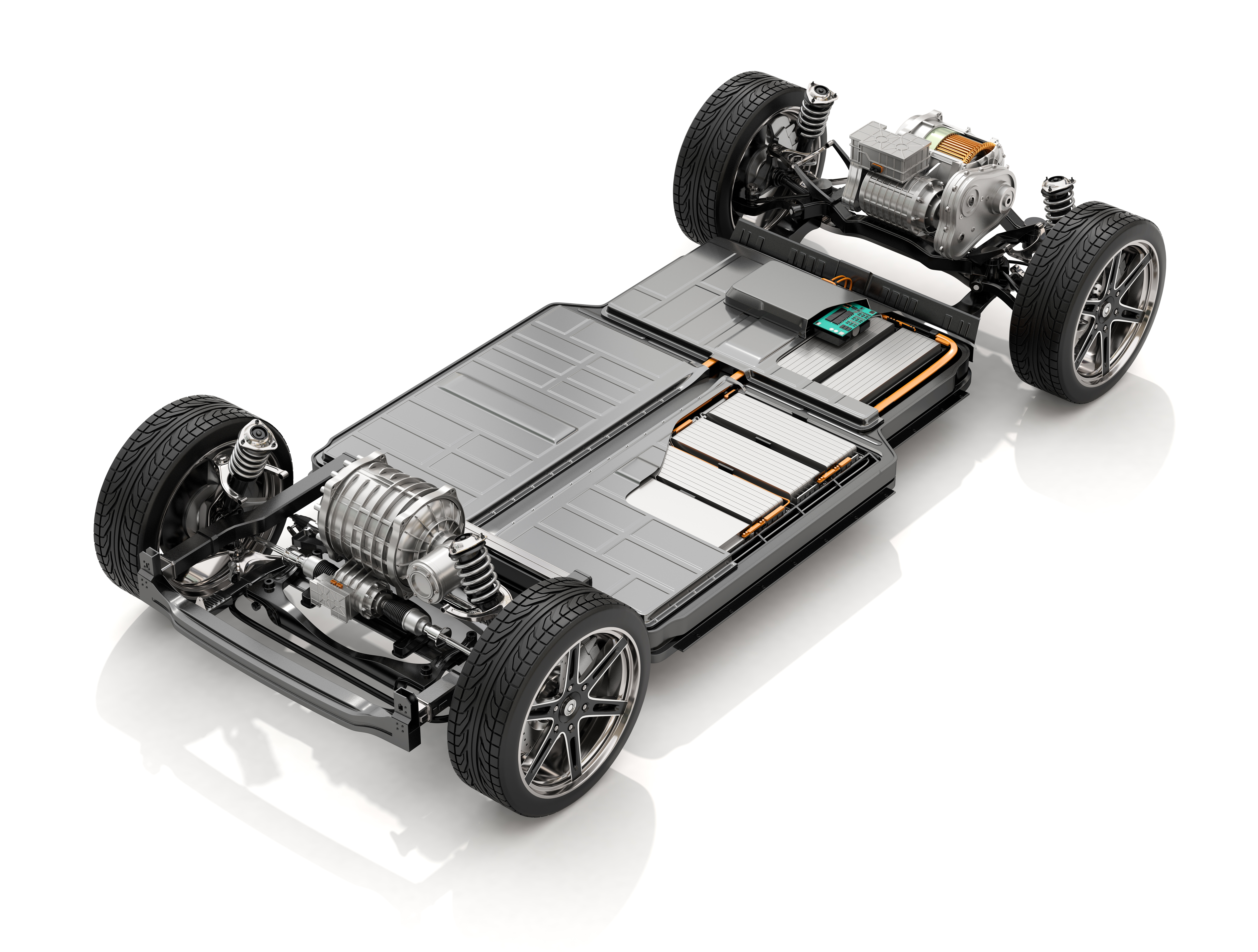

Many of the components in a vehicle remain the same between internal combustion engines and electric vehicles, such as wheel bolts, frame fasteners, and steering and brake components. While the engine and associated parts are replaced by drives and large battery packs, there are many new and upgraded components found in EVs that create opportunities as well. For example, battery packs require several additional smaller fasteners, suspension springs are often larger (due to increased vehicle weight) and extra springs are utilized to replace leaf springs that were previously made from flat rolled steel. In addition, there may be a need for higher strength and higher quality fasteners used to lighten vehicles and increase range.

Why Steel is Preferred for EV Parts

In addition to stepping away from alloy steels that were needed for high-temp applications. cleaner, smaller diameter, higher strength steel may be needed for EVs. EV manufacturers are choosing steel because it is a proven material in the auto space, plus it is cost effective and can be supplied to meet needed specifications. Steel, like Charter’s electric arc furnace produce, is a sustainable, low carbon footprint alternative to other materials as well. Development of cleaner steels have allowed for a reduction in weight while meeting the performance specifications of many components.

EV Component Manufacturers: Charter Steel’s Difference

With our historical automotive data and vast experience with clients in the automotive industry, Charter Steel is positioned with a deep technical bench and a world class lab for both development work and engineering support.

Unlike other steel mills, we live the automotive language with statistical process control (SPC), ISO certifications, high-quality, repetitive output, and more. As an approved supplier and partner, we can be flexible with testing and trials to create a more cohesive path for our customers. Using over 90% recycled content, our steel can help you meet carbon emission or sustainability goals as well. Charter Steel was the first steel mill in the country to be awarded ISO 50001 Certification-Energy Mgt. System and Implementation. That coupled with a local, Midwest supply chain makes Charter Steel the ideal choice for many components.

As we continue to invest in these resources and development work for the EV market, we take pride in understanding the differences and supporting updates as necessary to supply the EV market now and in the future.

If interested in learning more and meeting with our EV team, email cs-evinquiry@chartersteel.com. Stay tuned for future EV team webinars.