Decades ago, Charter Steel identified an opportunity to improve our steelmaking process by investing in electric arc furnaces (EAFs) at both our Saukville and Cleveland mills. This early adoption of EAFs improved the way we make steel, paving the way to delivering a cleaner and higher quality of steel to our customers, helping them grow and succeed with theirs.

Through the years, Charter Steel has continued to be on the forefront of innovation to produce the cleanest, highest quality steel possible from our EAFs. This includes ideal scrap procurement, melt enhancements such as refined scrap recipes, optimized slag practices, adhering to proper rinsing times in our Ladle Refining Furnaces, and improved technology to monitor the process. We also leverage downstream process to maximize the output of the EAF such as Vacuum Degassing, to produce high quality steel from our furnace. EAFs will continue to be a critical component in the steelmaking process for years to come as manufacturers & OEMs prioritize making a clean product for their customers.

What is EAF (electric arc furnace)?

EAF steelmaking uses electrical currents to melt scrap steel and other recycled metals. It’s more energy efficient while allowing for Increased flexibility in the steelmaking process.

The Steel Manufacturer’s Association estimates that 70% of the steel produced in the U.S. is EAF steel. Wood McKenzie, a research firm that specializes in renewables, energy and natural resources, estimates that “EAF share of global steel production will increase from the current 28% to almost 50% by 2050.”

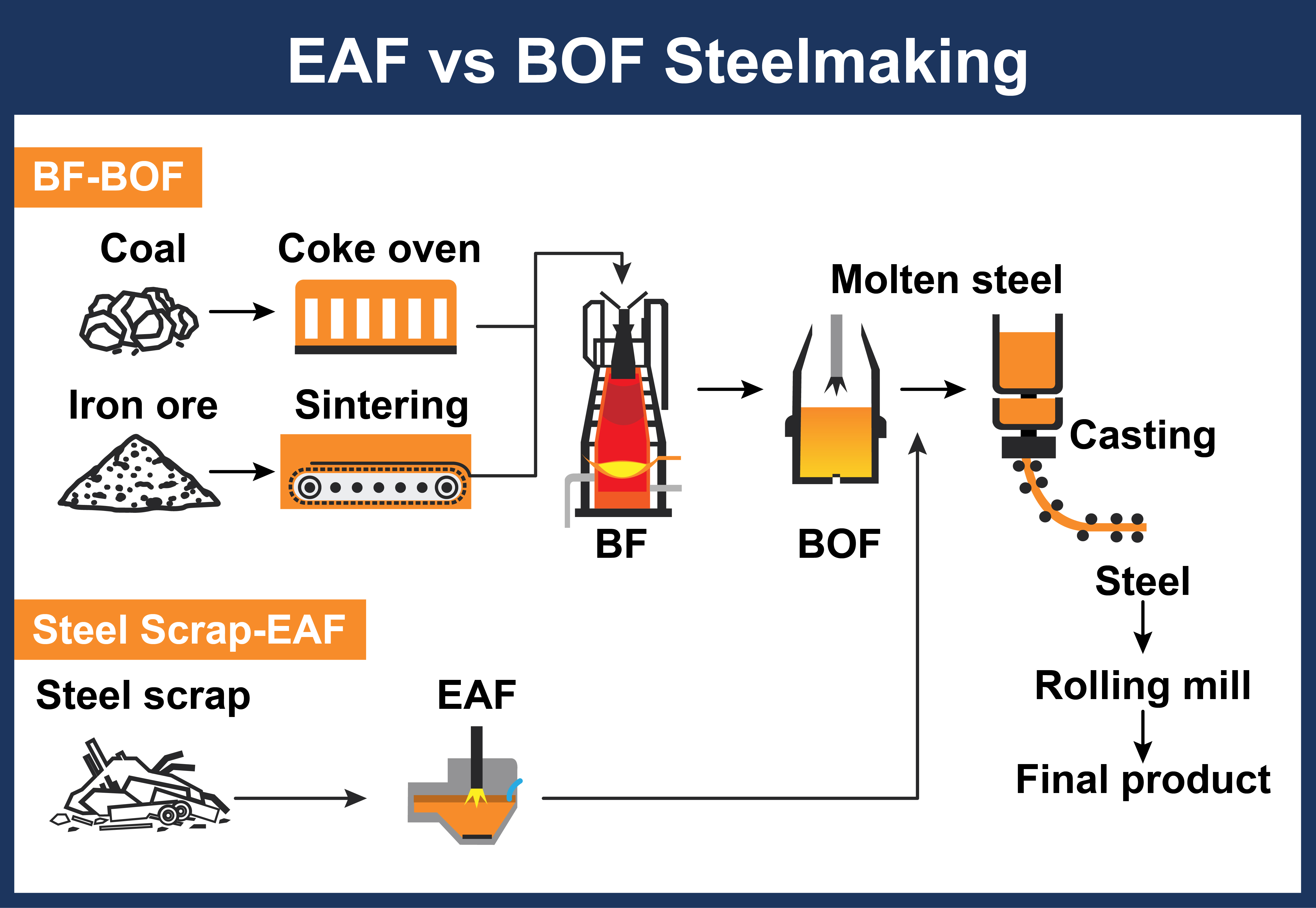

The Difference Between EAF and Blast Basic Oxygen Furnace (BOF)

While EAF steelmaking relies on electricity and recycled metals, Blast Furnace/BOF depends on raw materials like Iron Ore and Metallurgical Coke as part of a process where oxygen is blown into the furnace at a high velocity. This process uses significantly more energy, depends on using raw materials and is limited in its evolution towards more sustainable steelmaking.

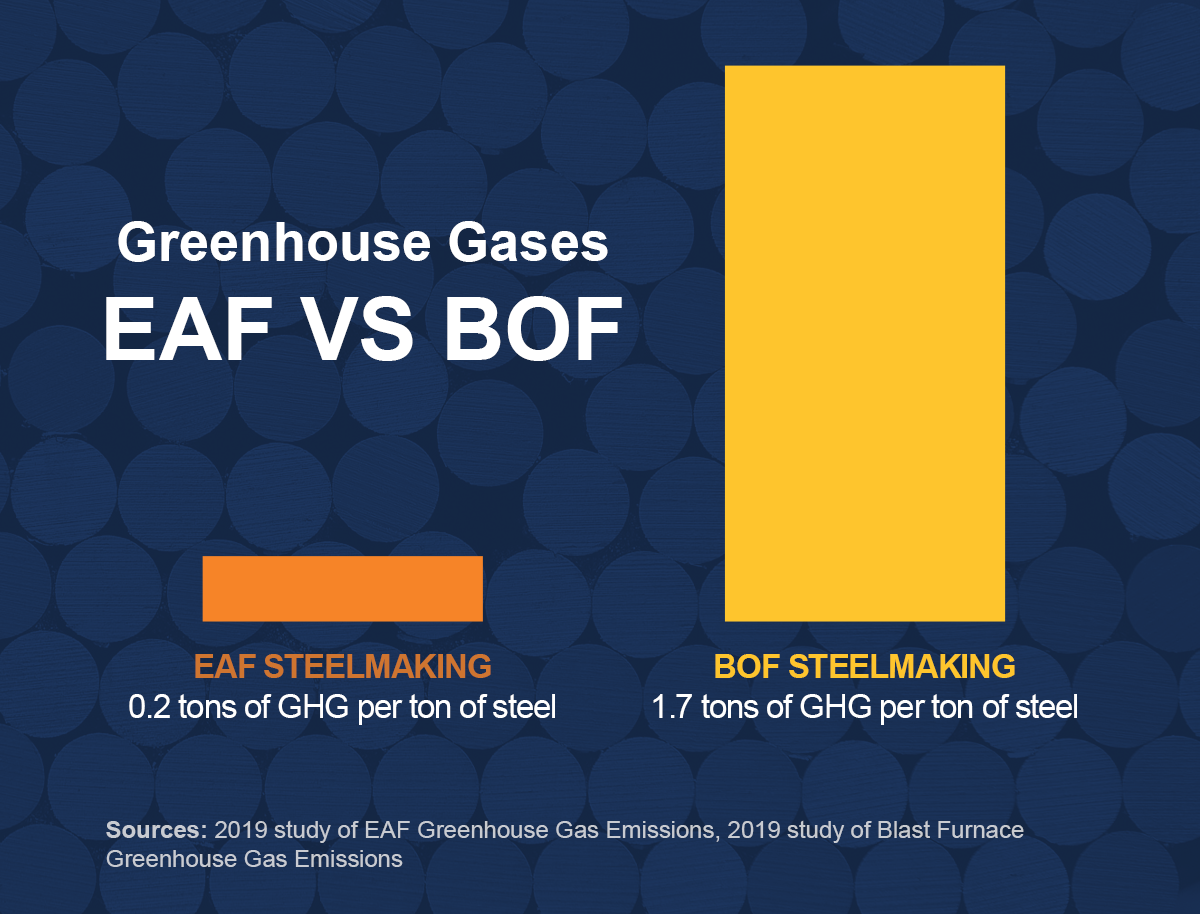

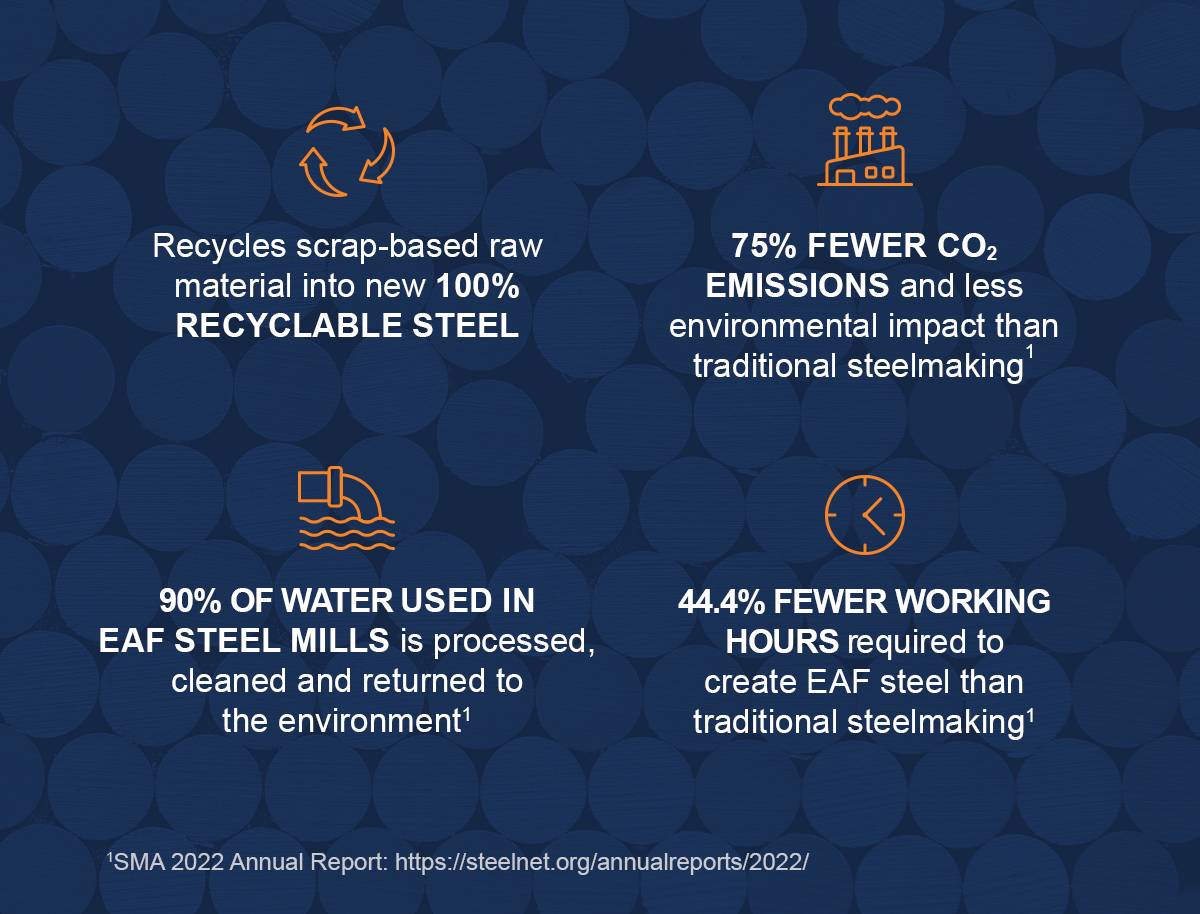

By using recycled steel as part of the EAF, we’re contributing to a circular economy—producing less landfill waste, using less energy and generating fewer emissions from production, transportation and shipping. The Steel Manufacturer’s Association claims that EAF operations produce twice the steel with 75% less greenhouse gas emissions over Blast Furnace/BOF production.

Environmental Benefits of EAF

EAF has proven to be a key component to making steel in a more sustainable way, benefiting the communities we work and live in everyday.

Connect with Charter Steel for Sustainable Steelmaking Solutions

We continue to make enhancements to our steelmaking process by investing in technologies and processes to align with customers goals of a high-quality product, produced through a clean process, with the added benefit of reducing the carbon footprint throughout each step of the way.

Have questions? Email us at sustainability@chartersteel.com.