Charter Steel’s Difference

Our highly specialized steel professionals have dedicated their careers to understanding our steel properties and being the best partner for our customers. As a true ally to our customers as part of our partnership, utilizing the lab comes at no additional cost. We deliver a fully transparent report with details and recommendations on solutions for customers needs.

We offer our guidance and expertise to our customers so they can in turn pass it on to theirs. No matter the project or steel materials, we can help determine any faults or other components that are worthy of analyzing.

Lab Advantage: Proactively Solving Problems

By pointing customers in the right direction from the start, we can prevent lengthy ‘trial and error’ periods by helping them solve problems typically within a one-week timeframe based on our data and expertise.

As metallurgical consultants and experts in the steel market, we test samples, troubleshoot and help our customers understand the efficiency and design of their products. Our expert team specializes in qualities of steel Charter offers – particularly cold headed quality steel. They understand these complex failure points, including chemistry checks that help customers better understand their product.

Our steel lab testing and capabilities allow us to extend our care for customers and help with any material issues that may arise. This is not limited to just steel, but we can support non-steel issues as well such as coating, manufacturing and application problems.

Our lab capabilities continually evolve as our customers' needs evolve. We have an ongoing commitment to investing in technology, and how Charter Steel’s team of experts are positioned to help solve problems and discover solutions for customers’ materials and application needs.

Lab Testing Overview

When a customer need arises Charter’s Technical Services lab technicians will begin their investigative process by:

- Receiving a customer’s material and/or material failures

- Gathering additional information on the material as needed

- Reviewing samples, requesting more samples, and working with operators or the customer as needed

- Following analysis, a detailed lab report is developed which summarizes work performed, findings, potential root cause and corrective actions.

Additional services provided by the lab include:

- Special projects with operations and customers to gather technical information and solve technical issues.

- Support customer troubleshooting on non-steel related issues

- Support trials and design of experiment methods to develop ideal steel properties to support a customer need. The lab being on site allows for most promising materials to be identified and shared with customers expeditiously.

Investing in Technology

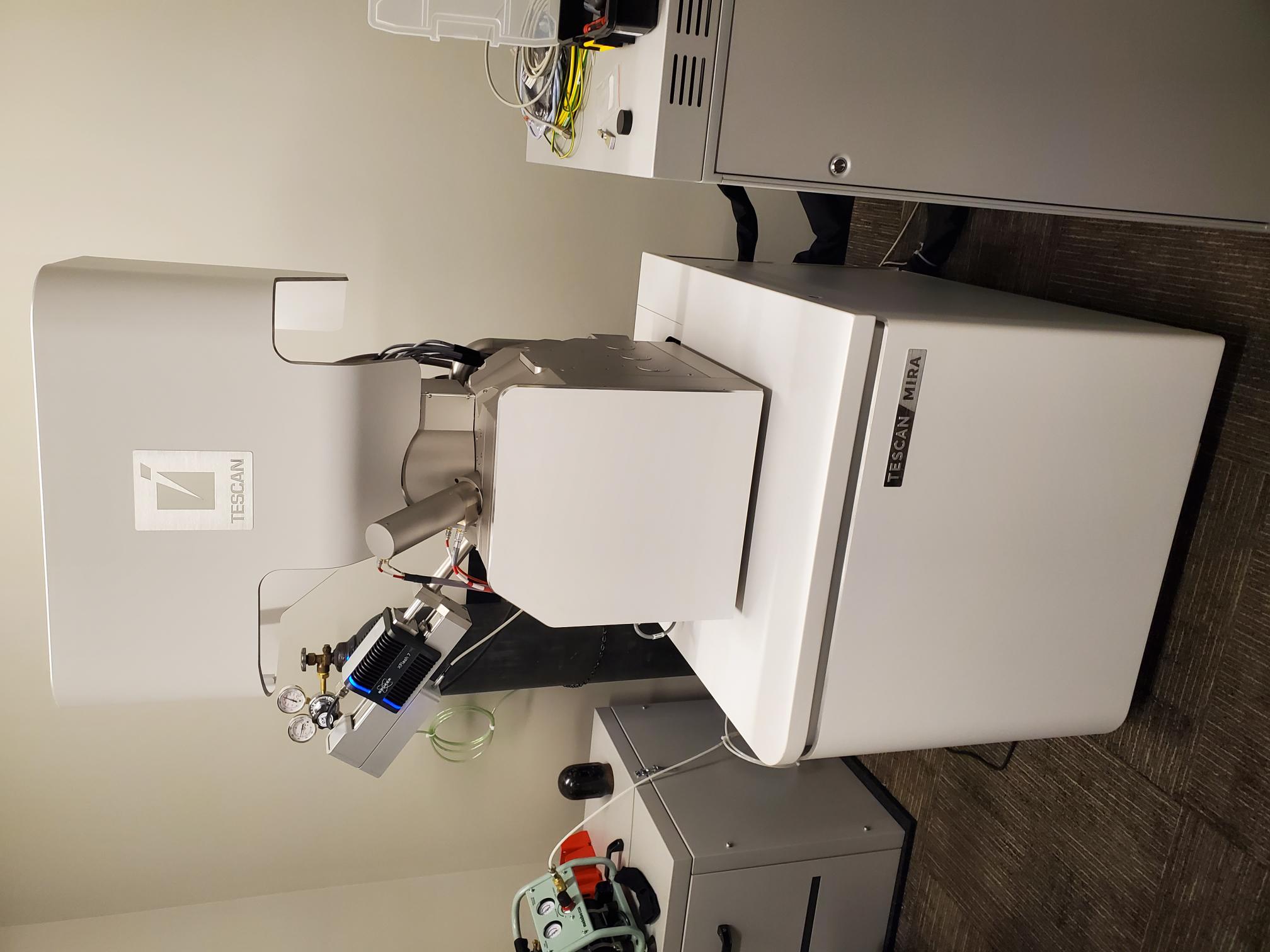

At Charter Steel, we’re continuously investing in our people, processes, and technology. Our new state-of-the-art field emission scanning electron microscope (SEM) delivers more capabilities than other technologies.

From automated inclusion analysis to seeing items that are hundreds of atoms across, our integrated analysis—paired with our SEM and EDS (Energy Dispersive Spectroscopy)—allows us to identify the inclusions, residues, different types of coating, corrosions, failure modes, and more to help identify a solution for our customers.

We can then work with our melt, roll and processing teams to determine the origins of these issues, and what we recommend doing in the future to reduce these occurrences. With our innovative SEM, we can add more capabilities allowing us to continue discovering solutions and serving our customers with their steel needs.

To utilize our lab testing capabilities and on-site analysis, contact your dedicated technical service engineer (TSE).