Charter Steel has been making environmental investments for decades. We value the communities we serve and the places our employees live and work. Sustainability isn’t just a catchphrase at Charter—we live it.

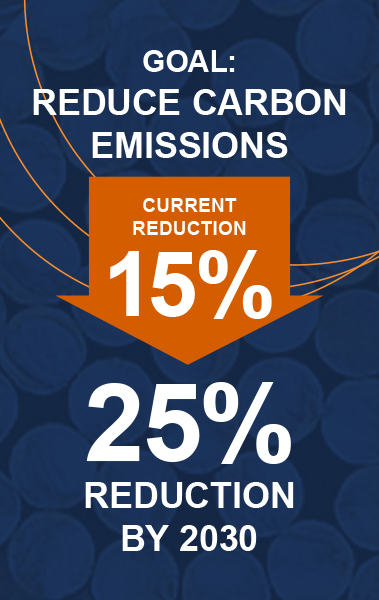

Our goal is to achieve a 25% reduction in carbon emissions (currently at 15%) by 2030. With our continuous improvement mentality and investments in our employees and resources, we’re committed to helping the environment and our communities.

Let’s review a variety of projects that have built the foundation of our sustainability efforts and the new projects that will impact carbon reduction as we continue to make progress towards our goal.

Our Employee-Led Energy Teams

Over the years, Charter has established important partnerships with Focus on Energy, the U.S. Department of Energy, Energy Star and more. These partnerships continue to lead to a variety of sustainable and cost-saving benefits, as well as historic milestones.

As the first steel mill in North America to obtain ISO50001, we dedicated ourselves to implementing a formal energy management system that meets the requirements of the International Organization for Standardization (ISO), which is audited and certified by a third party.

Each of our Charter Steel plants has

an energy team made up of frontline employees, engineers and other stakeholders. These teams identify energy reduction opportunities and get others engaged to identify and implement projects that impact the company as well as the environment. Our culture drives improvement in all we do from our performance to our sustainability efforts, and our team members are at the forefront of making things better every single day.

Charter’s Green Initiatives

One of Charter Steel’s earliest investments toward sustainability was the electric arc furnace (EAF). While many manufacturers were utilizing basic oxygen furnaces (BOF), we saw an early opportunity to lead the industry with EAF, which are used in both the Cleveland and Saukville facilities.

Using electrical currents to melt scrap steel and other recycled materials, EAF is more energy efficient while allowing for significant flexibility in the steelmaking process. From the start, Charter Steel has recognized the benefits of EAF steelmaking and its essential impacts on the environment:

- Recycle scrap-based raw material into new 100% recyclable steel

- Recycled content in Charter Steel – on average – was greater than 90% in 2022

- 75% fewer CO2 emissions and less environmental impact than traditional steelmaking1

- EAFs are used to produce over 70% of American steel, compared to 28% by steelmakers worldwide1

- 90% of water used in EAF steel mills is processed, cleaned and returned to the environment1

- 44.4% less man hours to produce EAF steel than traditional steelmaking1

1SMA 2022 Annual Report: https://steelnet.org/annualreports/2022/

Completed Project: Scrap Preheat

When determining how to improve indoor air quality for our employees, the scrap preheat system was identified as an opportunity to reduce fugitive dust inside the plant, greenhouse gas emissions and energy use per ton.

Historically, around 100 tons of scrap steel was dropped into the open EAF which did not recover any energy from the heat. This allows us to keep the EAF roof in place and uses a series of conveyors to slowly feed scrap metal into the furnace.

The project yielded tremendous results:

- Saves approximately $4 million per year

- Reduced dust in the facility by 73%

- Reduced annual electricity consumption by 2.25 million kWh

- Lowered hazardous waste by 3.5 million pounds annually

- Reduced annual greenhouse gas emissions by 14,000 tons

The success of this project was recognized with awards from two highly reputable organizations. Charter won the 2022 Better Project Award from the U.S. Department of Energy’s Better Plants Program and the 2021 Business Friend of the Environment Award from Wisconsin Manufacturers and Commerce.

Current Project: Saukville Solar Field

Charter Steel is currently in the implementation phase of the Saukville solar field, which is expected to generate an estimated 27 million kWh of electricity per year, (the equivalent of powering approximately 3,700 homes per year in Wisconsin). Owned by Charter Steel, the solar facility is on 60 acres of Charter Steel’s existing land. The energy will be collected and used “behind the meter”, meaning it will not utilize the utility energy grid for supply. This is one of the largest behind the meter solar facilities in the Midwest.

The solar panel materials are solid and sealed within the panel. The steel is the same material used for utility poles, such as light poles, traffic signs and similar uses. Some of the notable advances have come in making sure solar projects can coexist with local wildlife, including the development of landscaping plans to incorporate pollinator gardens that help sustain bird and bee populations.

This solar project is designed to be operational for an estimated 30-35 years. The design calls for three areas with solar panels, all of which will be setback from existing property lines consistent with or greater than requirements established by the Town of Saukville.

Charter’s Sustainable Future

At Charter we’re committed to our people, the environment, and sustainable business practices. As a result, past, present and future generations will have their own sustainability stories to tell. To learn more about Charter Manufacturing’s commitment to sustainability, read the inaugural 2022 Sustainability Report.

For additional questions on Charter Steel’s sustainability efforts, please email sustainability@chartersteel.com.